| Performance example | Conventional solid copper plunger tip | Copper plunger tip with Copromec ring |

|---|---|---|

| Cost | €300 |

|

| Life for piece | 5,000 injections |

|

|

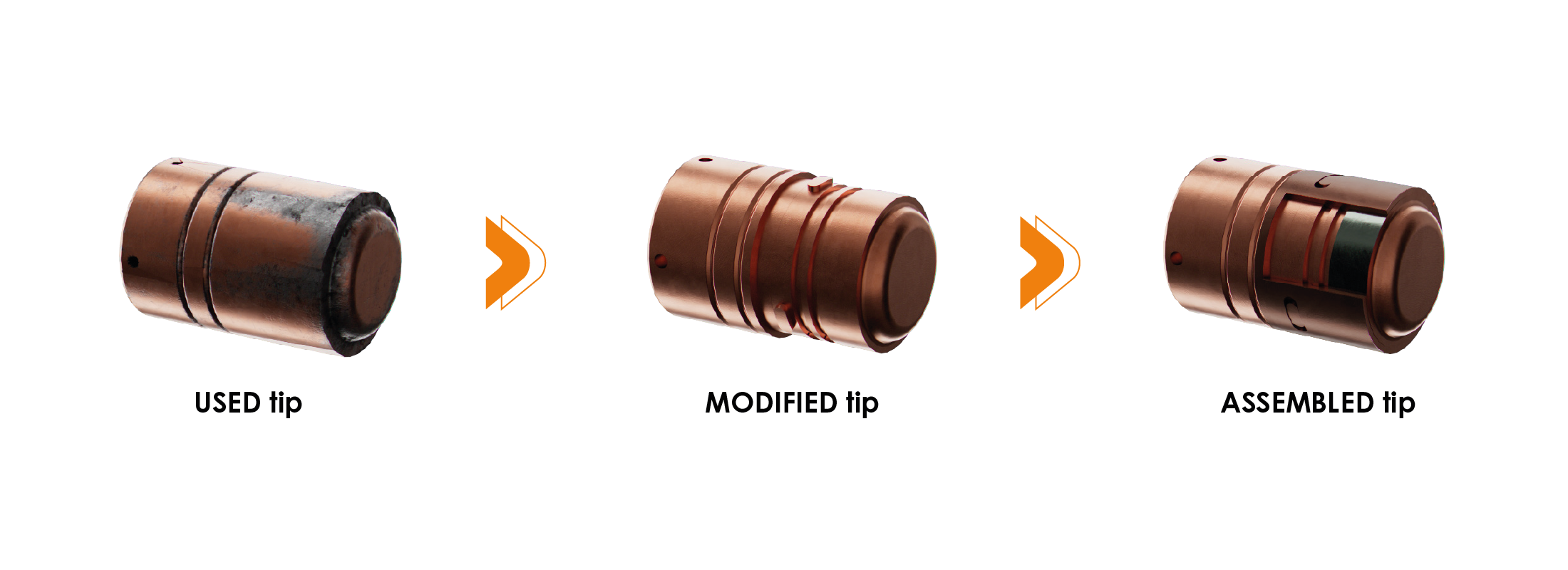

Adapt Costs sustained for 50,000 injections |

10 plunger tips → €3,000 |

Total: €1,050

|

| Pieces used |

|

|